|

Baoji Allipower Equipment Co., Ltd

|

Coiled Tubing Pressure Control Equipmen

| Payment Terms: | T/T |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Coiled Tubing PCE is applied for coiled tubing Workover, Flushing, Subsidiary cable Logging and so on.

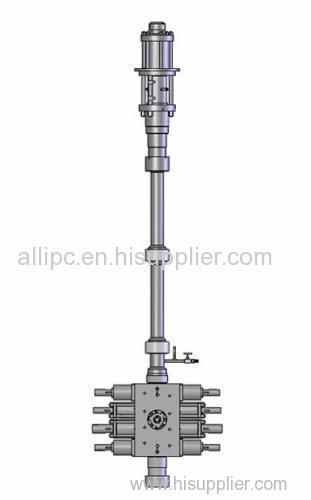

Coiled Tubing PCE

Coiled Tubing PCE is applied for coiled tubing Workover, Flushing, Subsidiary cable Logging and so on.

Simple structure& Easy of use and fix are mainly characteristic. It is small and light, but could work under high pressure and H2S conditions.

Coiled Tubing PCE includes of 5 mainly parts, such as Side Door Stripper, Lubricator, Hydraulic Quad Ram BOP and Wellhead Crossover Flange, Blowout Sub.

Technical parameters:

1. Sealing Tubing OD:

1" , 1 1/4" , 1 1/2" , 1 3/4" , 2" , 2 3/8" , 2 7/8" , 3 1/2"

2. ID of BOP and Lubricator:

62mm, 76mm, 89mm, 101.6mm, 127mm, 180mm

3. Working Pressure:

21MPa, 35MPa, 70MPa, 105MPa

4. Connection Thread:

According to requirement, UNION, Flange etc.

5. Working circumstance:

Crude Oil, gas and water with H2S (H2S service standard: EE).

6. Working Temperature:-29°C~+121°C

Side Door Stripper:

It is easy to replace the Packer Element. In the process of operation, the replacement could be done when closing half-sealing ram and opening side door& up piston. It is no need to pull out tubing, which saves much time.

Hydraulic Quad Ram BOP:

Hydraulic is required to open and close the ram. The Hydraulic Quad Ram BOP could be used for sealing well (tubing inside). It could seal well when cutting off tubing in emergency.

Lubricator:

The Lubricator is fullbore and could work as buffer for string tools. Single and total length could be decided from real operations.

Wellhead Crossover Flange:

The Wellhead Crossover Flange is on the bottom of Coiled Tubing Pressure Control Equipment. It is used to connect the Lubricator and Wellhead.

Blowout Sub:

When device is pulled up into Lubricator and Wellhead valve is closed, Blowout Sub is used to release left pressure in Lubricator. Then Coiled Tubing PCE could be disassembled. Pressure Gauge on Sub shows

wellhead pressure.

Related Search

Pressure Control

Pressure Control Valve

Pressure Control Switch

Electronic Pressure Control

Tubing

Steel Tubing

More>>